08/09/2017

During the socio-economic development, under the impacts of natural factors and human activities, a variety of environmental problems are occurring. One of the most emergent issues need to be handled is the pollution from domestic solid wastes. The Vietnam Environment Administration has assigned the Center for Environment Consultancy and Technology to implement a pilot project on treatment technology for domestic solid wastes in rural areas in Việt Nam in accordance with New Rural Program in Việt Nam. The project has been implemented and achieved three important indicators: (1) To totally treat domestic solid wastes in order to meet the current standards and regulations; (2) To ensure the sustainability of the project with low treatment cost; (3) The machines and equipment for the project shall be manufactured domestically, and easy for operation and appropriate with the workers’ capacity in the rural areas.

The project was implemented in Hồi Ninh commune, Kim Sơn district, Ninh Binh province which is one of the prominent areas for Viet Nam’s rural areas in Nhuệ - Đáy river basin. The project constructed and completed for operation and handled to the local authority with the capacity of four tons/day.

I. Treatment technology

Treatment technology diagram of the project

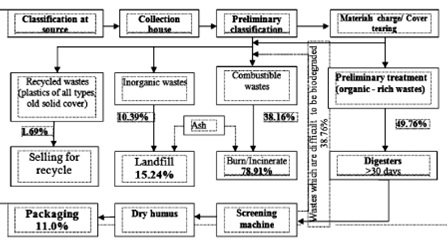

The treatment technology process of the project consists of the following main steps: classifying wastes at sources; transporting and collecting wastes; preliminarily classifying wastes; tearing covers and stirring wastes; collecting recycled wastes; burning wastes; landfill inginorganic wastes and composting, producing organic humus. The detailed process of treatment is presented below:

(1) Classifying at source: Wastes are sorted at source at households in the commune into two categories as required by the project, including: inorganic wastes (chinaware pieces, porcelain, bottles, broken bricks, ...) and the remaining synthetic wastes (mostly organic and combustible wastes). The inorganic wastes are contained in separated bag before moving to the communal collection vehicles to transport to the treatment area.

(2) Collecting wastes: Wastes are transported from the residential areas to the treatment areas twice a week (on Thursdays and Sundays); at the sorting and composting house,wastes are stored prior to treatment according to the process. Right after collection, wastes are sprayed with probiotics for deodorant and anti-flies. Periodically, in two weeks, wastes are processed every Mondays.

(3) Preliminarily classifying: Wastes will be classified preliminarily to separate inorganic wastes that were sorted at source (bricks, stones, pieces of crockery, pieces of glass …)

(4)Tearing cover and stirring waste: After preliminary classification, the remaining wastes are contained in bags and torn and stirred by machines, in which wastes are mixed to enhance the effectiveness of exposure and compost process. The remaining rich organic wastes will be composted.

(5) Preliminary treatment: At the floor of the composting house, the organic-rich wastes are mixed with probiotics in accordance with the guidance of the project prior to the composting process in the digesters.

(6) Composting at digesters: The anaerobic decomposition process is very complex which relates to hundreds of reactions and types of intermediate products. However, in the organic-rich waste treatment, the composting process can be considered as a stable biochemical process of organic matters to turn into humus, with scientifically controlled steps of manufacturing, creating the optimal environment (temperature: 40-55oC, humidity: 50-52%), composting process also generates heat due to the oxidation of rotting substances. This process is complicated resolution of carbohydrates, lipids and proteins, with the participation of anaerobic microorganisms. The composting principle is using the added microorganisms selectively (to shorten the incubation time). Used microorganisms are bacteria lactobacillus and saccaromyces, which aim to resolve organic compounds, thereby shorten the composting time to about 30 days.

To optimize this incubation stage, the project has launched an effective, simple and manually operated process of incubation to reduce costs as well as to meet the requirements for the qualification of operators. In the composting process, periodically 1-2 days (depending on the season) to conduct additional spraying to control the factors of humidity, temperature and to supplement microbiological substances for the completely decomposed wastes. In addition, the anaerobic composting process will also eliminate some pathogens from the original wastes, reduce the moisture in the persistent organic parts that facilitates the combustion.

Guiding people in Hồi Ninh commune to classify the wastes at source

(7) Screening to collect the organic humus: After incubation according to the regulated time, the digesters are uncovered and open ≥ 24 hours. Wastes are moved to screen machine, then separated into organic humus and the remaining non-organic humus. The organic humus is put under the sun (or to dry naturally) to ensure moisture as required before packaging and storing in the warehouses. The non-organic ingredients are brought to the incineration unit. The quality of organic humus must meet some of the technical indicators for organic fertilizers according to National Standard TCVN 7185: 2002 applied to the organic fertilizers for soil.

(8) Incinerating: Combustible wastes are collected from the stage of preliminary classification (38.16%) and partly non-organic wastes (organic wastes are difficult to be biodegraded ~ 38.76%) from the stage of classification to collect organic humus. The total amount of wastes burned is 76.91%. The relatively dry wastes (humidity ≤25%) will be burned earlier. The higher humidity wastes will be dried on the concrete deck or burnt on the floor. The incineration will be conducted when collecting wastes are enough to burn continuously for at least one working day (one shift) or burn for several continual days.

The incineration technology does not absolutely use fuel, incinerators designed to ensure compliance with regulations, hazardous constituents in ash after combustion guaranteed under QCVN 07: 2009/BTNMT - The threshold for hazardous wastes, waste gas from the incinerators are handled at two levels in compliance with QCVN 30: 2012/BTNMT - National technical regulations on industrial waste incinerators before getting into the chimney and discharged into the environment.

(9) Landfilling inorganic wastes: The wastes that shall be landfilled including inorganic waste from the stage of preliminary classification (~ 10.39%) and the incinerator ash (~ 12.7% compared to the burning wastes). The total amount of waste sent to landfill is 15.24% (percentage burial). In addition, the project will use a part of ash to mix with the organic humus and soil to plant cassava and pumpkin... that brings economic efficiency and reduces landfill rate to about ~ 10%.

(10) Recycled wastes: The recycled wastes are classified, stored and sold periodically to the organizations which have capacity and operation licenses and use the recycled wastes for recycled materials. These wastes consist mostly of solid old sacks (1.36%) and plastics of all kinds (0.33%).

Waste treatment incinerator

II. Economic efficiency and model replication possibility of the project

Economic efficiency is one of the most important criteria to be able to replicate this technology and it is the sustainability of the model, based on the balance of income and expenses while operating the model. Revenues from waste collection combined with revenues from the recycled products can be fully offset in order to maintain regular efficient operation of the plant.

In addition, the project model also meets the most important criteria to be able to ensure the feasibility of replication in other locations, as follows:

- Technology has thoroughly handled the amount of generated wastes and to meet the current environmental standards and regulations;

- Partly reuse of organic humus (for soil improvement) and partly recycling of wastes, ... contributing to maintain the operational costs;

- Low landfill percentage, about 15.24% (possibly lower if ash is partially reused for farming purposes for some crops, such as cassava plants and pumpkin ...);

- No leachate generated, so no extra cost for leachate treatment;

- System of machinery, equipment and technology is not complicated, can be made locally, easy to operate, maintain and replace when there are damages, ... matching qualified operators locally.

The project has successfully developed a pilot model of management and treatment of domestic solid wastes in the rural areas with the capacity of four tons/day that can be applied in residential areas (communal or inter-communal) and has been applied successfully in Hồi Ninh commune, Kim Sơn district, Ninh Bình province. The project has launched a technology solution for handling domestic solid wastes in the rural areas which is relatively consistent with the conditions of Vietnam; it has many advantages for replicating the model to other regions.

The result of the project is an important solution to solve one of the criteria of New Rural Program, which is the criterion of environmental sanitation (waste problem) and thereby contributing to the success of the implementation of the National Strategy on managing solid wastes to 2025 and vision to 2050.

MSc. Vũ Ngọc Tĩnh

MSc. Đàm Văn Vệ

Center for Environment Consultancy and Technology

Vietnam Environment Administration