08/01/2024

Abstract:

Coal-fired power plants (CFPPs) are an important energy source and the major source of air pollutants as well as greenhouse gases (GHGs) in Vietnam. The emission data of air pollutants and GHGs are an important base for setting up control strategies and management policies. This study assesses the emissions of PM2.5, PM10, SO2, NOx, CO, CH4, N2O, and CO2 from CFPPs in Vietnam in 2019, and 2021 and predicts those in 2030 based on coal consumption and emission factors. A method to estimate PM2.5 and PM10 emission based on the emission of PM and size distribution was proposed to overcome the difficulty of lacking data and measuring those parameters in the flue gas in Vietnam.

Keywords: Coal-fired power plants, emission inventory, PM2.5.

JEL Classification: Q51; Q53; Q54.

Received: 23th September 2023; Revised: 18th October 2023; Accepted: 3rd November 2023.

1. INTRODUCTION

CFPPs are one of the main sources to air pollutants as well as greenhouse gases GHGs emissions in Vietnam. In recent years, air pollution has been a major environmental concern in Vietnam (Huy and Oanh, 2017). For example, the concentration of PM2.5 in many provinces and cities in Vietnam has exceeded the allowable limit of the national standards on ambient air quality and is several times higher than the recommended levels of World Health Organization guidelines (Hien et al., 2019; Thanh et al., 2019; Ly et al., 2018).

In 2019, Vietnam had 28 CFPPs in operation with an installed capacity of 19,744 MW, accounting for 35.83% of the total installed capacity of the power system (EVN, 2022). The total capacity of electricity produced from CFPPs has developed rapidly over the past decade. CFPPs have been projected to be the main power source (Roy et al., 2021, 2022). However, currently, Vietnam has issued a new National Electricity Development Plan for the period 2021 - 2030, vision to 2050 (Power Development Plan VIII - PDP8), which significantly reduce the percentage of CFPPs to 20% of the power source structure in 2030, corresponding to a capacity of 30,127 MW. This adjustment is considered as one of Vietnam's efforts to decrease GHGs emissions by 8% in 2030 as agreement made in COP21.

Assessing the emissions of CFPPs is very important to develop strategies and plans to control air pollution and minimize the contribution to global warming. There were three publications on air pollution emission of CFPPs in Vietnam, in 2010 (Huy & Oanh, 2017), 2015 (Roy et al., 2021), 2019 (Roy et al., 2022) and emission scenarios according to PDP7 revised (Roy et al., 2022). The emission scenarios according to PDP8, which has a significant reduction of contribution of CFPPs in power source structure, are not yet available. This study aims to develop an emission inventory in 2019 (based year), in 2021, and forecast emissions according to PDP8 in 2030. Compared with Roy et al., 2022, the overall methodology in this study is similar, but as this research is conducted later the data on coal consumption, coal characteristics are more updated. Besides, there are some different approaches in the selection of calculation parameters.

2. METHODOLOGY

2.1. CFPPs and activity data

Twenty-eight CFPPs were operating in Vietnam in 2019, of which 19 plants use pulverized coal (PC) boilers and nine plants use circulating fluidized bed (CFB) boilers. The total installed capacity of CFPPs using CFB and PC technology is 3,420 MW (24%) and 15,638 MW (76%), respectively. Most of the CFPPs are located in the significant coal mines and key economic zones of the Northern, only seven and three plants are in the Central and Southern regions of Vietnam.

Activity data of CFPPs are critical information to estimate annual emissions from each CFPPs using a bottom-up approach. Besides, emissions from coal combustion depend on coal type and its composition, the design type and capacity of the boiler, the firing conditions, load, the types of control devices, and the level of equipment maintenance (US-EPA, 1996).

Most of the activity data used in this study were collected from local and national sources. Location, installed capacity, boiler technology, and total electricity output (GWh) were obtained from local reports. The coal consumption and coal properties including net calorific value (NCV), ash content, and sulfur content were mainly extracted from CFPPs reports. In case, data on coal consumption is not available (in 2019), the number was calculated based on electricity capacity and coal consumption rate. The activity data for operated CFPPs in 2019 and 2021 are summarized in Table 1 and Table 2.

Table 1: Summary of boiler technologies of operating CFPPs in 2019 and 2021

|

|

Technology |

Total |

||||||

|

CFB |

PC |

|

||||||

|

Sub Critical |

Super Critical |

|||||||

|

2019 |

2021 |

2019 |

2021 |

2019 |

2021 |

2019 |

2021 |

|

|

Number of plants |

9 |

10 |

16 |

16 |

3 |

4 |

28 |

30 |

|

Installed capacity[a], MW |

3,390 |

4,590 |

12,598 |

12,598 |

3,040 |

3,728 |

19,028 |

20,916 |

|

Coal consumption, 103 tons |

9,846[b] |

15,395[c] |

34,729[b] |

32,437[c] |

8,649[b] |

7,318[c] |

53,224 |

55,150 |

|

Amount of coal per electricity production[d], ton MWh |

0.459 |

0.596 |

0.437 |

0.493 |

0.424 |

0.448 |

0.440 |

0.512 |

|

Electricity production, 103 MWh |

20,705[e] |

29,149[c] |

77,605[e] |

74,340[c] |

20,000[e] |

16,874[c] |

119,310 |

120,362 |

Note: a, c - EVN, TKV, CFFPs reports (2019, 2022); b - Annual fuel consumption = Total annual actual electricity produced (kWh) * 3600 (kW/kJ)/Boiler efficiency (%) * NCV (kJ/kg)); d - Amount of coal per electricity production = Coal consumption (ton/yr)/Electricity production (MWh/yr); e - Electricity production = Installed Capacity * 320 (h/yr)

It is important to note that the electricity production in 2020 and 2021 were affected by COVID-19. Therefore, the yearly increase in electricity production is lower than in the previous period. The electricity productions in 2019 and 2021 are almost the same.

For the prediction of 2030 emissions, the total electricity production is chosen following PDP8 (designing value of electric production). The emission rate of all pollutants and GHGs per electricity production of total CFPPs in 2019 was multiplied by the electricity prediction to obtain the emission in 2030.

Table 2: Summary of coal types of operating CFPPs in 2019 and 2021

|

|

Anthracite |

Bituminous/Subbituminous |

Lignite |

|||

|

2019 |

2021 |

2019 |

2021 |

2019 |

2021 |

|

|

Number of plants |

21 |

22 |

6 |

7 |

1 |

1 |

|

Coal consumption amount, 103 tons |

37,229[a] |

41,078[b] |

15,571[a] |

13,566[b] |

424[a] |

506 [b] |

|

Amount of coal per electricity production[c], ton/MWh |

0.59 |

0.55 |

0.45 |

0.47 |

0.61 |

0.67 |

|

Electricity production[c], 103 MWh |

63,460[d] |

74,381[b] |

34,850[d] |

29,107[b] |

700[d] |

756[b] |

Note: a - Annual fuel consumption = Total annual actual electricity produced (kWh) * 3600 (kW/kJ)/Boiler efficiency (%) * NCV (kJ/kg)); b - Collected; c - Amount of coal per electricity production = Coal consumption (ton/yr)/Electricity production (MWh/yr); d -Electricity production = Installed Capacity * 320 (h/yr)

2.2. Emission calculation

2.2.1. Equation

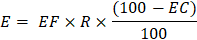

The amount of polluted gas emitted by CFPPs was calculated according to Equation 1:

(1)

(1)

Where: E is the amount of emissions (tons/year); R is activity data (coal consumption (tons/year) for air pollutant estimation; the heat of burned coal (KJ/year) for GHGs estimation); EF is emission factor corresponding to the amount of activity (kg/tons) for pollutants; (kg/TJ) for GHGs; and EC (%) is the efficiency of control systems.

2.2.2. Emission factor of gaseous pollutants

For air pollutants including PM (filterable particulate matter), NOx, SO2, and CO, EFs were extracted from the AP-42 document (EPA, 1998). For greenhouse gases including CO2, CH4, N2O, EFs from the IPCC-2006 document (IPCC, 2006) were applied as presented in Table 3. The EFs of PM2.5 and PM10 were discussed and determined in Section 3.1.

Table 3: Uncontrolled gaseous pollutants EFs of CFPPs

|

No. |

Parameters |

EF[1] |

EF[2] |

Unit |

|

|

PC boiler |

CFB boiler |

- |

|||

|

1 |

PM |

5A[a] |

5A[a] |

- |

kg/tons coal |

|

2 |

SO2 |

19.5S[a] |

1.45[a] |

19S (for anthracite and bituminous)[c], 15S (for lignite)[c] |

kg/tons coal |

|

3 |

NOx |

9[a] |

0.9[a] |

5.02 - 6.79 (for anthracite)[c], 7.74 - 8.2 (for bituminous)[c], 9.03 (for lignite)[c] |

kg/tons coal |

|

4 |

CO |

0.3[a] |

0.3[a] |

0.33 - 0.45 (for anthracite)[c], 0.34 - 0.36 (for bituminous)[c], 0.14 (for lignite)[c] |

kg/tons coal |

|

5 |

CO2 |

98,300[b] |

98,300[b] |

98,300 (for anthracite), 94,600 (for bituminous), 101,000 (for lignite) |

kg/TJ |

|

6 |

CH4 |

1[b] |

1[b] |

1 |

kg/TJ |

|

7 |

N2O |

1.50[b] |

1.50[b] |

1.50 |

kg/TJ |

* Note: A - ash content of coal (%); S - the percentage of sulfur content in coal; a - AP42 (EPA, 1995); b - IPCC (IPCC, 2006), c: Calculated from the research of Roy et al. (2022); 1 – EFs used in this study; 2 - EFs used in Roy et al. (2022).

2.3. Pollutant control efficiency

Unlike activity data, data about treatment efficiencies for air pollutants are not available in terms of operating values but only designing values. However, not all design treatment efficiencies are available. Therefore, we reviewed the current treatment systems and determined the best guess numbers for operating treatment efficiencies based on the types of installed devices or design efficiencies. This method is subject to large uncertainty but is considered to be the most suitable method for the time being.

2.3.1. Particulate matter treatment and efficiency

All CFPPs in 2019 installed electrostatic precipitator (ESP) systems with design efficiency of particulate matter treatment higher than 99.7% (Luong, 2018); 99.6% (EVN, 2019) or 99.19% in some plants (gathered from our communication). The operating efficiencies can be affected by several factors (such as the electric voltage, physical conditions of ESPs, fly ashes characteristics, and the shifting of operation temperature after a long time operation) and normally lower than designing one depending on the maintenances. In this study, the treatment efficiency for PM of 99.2%, which is equal to US.EPA - AP.42, was applied for all plants (Table 4). Unfortunately, there is no local available information regarding the treatment efficiencies of PM2.5 and PM10.

2.3.2. SO2 control and efficiency

SOx emissions in current CFPPs in Vietnam were controlled by two types of technologies: controlling in the boiler (applying for CFB boiler); flue gas desulfurization (FGD) (mainly divided into two solutions: SO2 absorption by slurry limestone and SO2 absorption by sea water). All CFB plants remove SO2 in boilers by injecting limestone (CaCO3) into the fire chambers, where SO2 reacts with limestone to form CaSO4 which can be discharged as ash and slag. Some plants have additional FGD for further treatment of SO2. Most PC plants apply SO2 treatment technology with limestone/Mg(OH)2 or seawater. The method of treating SO2 with limestone is very popular in the world and has been tested through manufacturing and operation. This method has a high efficiency of up to or over 90%. The seawater absorption method is a modern technology, currently applied to new CFPPs in Vietnam such as Vinh Tan 2, Duyen Hai 1, Vung Ang 1, Vinh Tan 4, Duyen Hai 3... This technology uses cooling seawater from condensers to absorb and neutralize SOx in exhaust smoke. The SOx removal efficiency of this technology can be up to over 90% (EVN, 2018; Luong, 2018).

The treatment efficiency of 90% for SO2 was applied for all PC CFPPs and 0% for CFB CFPPs.

2.3.3. NOx control and efficiency

There are two main methods for controlling NOx emissions in CFPPs in Vietnam: controlling NOx emissions in boilers and treating NOx in exhaust gas. Currently, NOx treatment methods at PC CFPPs in Vietnam vary from using low NOx emission nozzles/burners to equipping selected catalyst reactor (SCR) equipment. The processing efficiency of the SCR device for NOx treatment can reach about 75-80%. For CFB plants, NOx treatment devices are not installed due to low combustion chamber temperatures, but emissions can still comply with the National Technical Regulation on Emission (EVN, 2018; Luong, 2018).

The treatment efficiency of NOx was chosen of 0% for CFB CFPPs and 30% for PC CFPPs, except for seven plants with SCR (Vinh Tan 1, 2, 4 and 4 extension, Mong Duong 2, Duyen Hai 1 and 3 with efficiency of 65-88.4% extracted from Roy et al., 2022).

2.3.4. CO, CH4, CO2 control and efficiencies

There is no CO, CH4, CO2 treatment for CFPPs in Vietnam. Therefore, the treatment efficiencies of those compounds are considered as 0%.

Table 4: Summary treatment efficiencies of PM, SO2, and NOx of previous and current CFPPs emission inventory research

|

Sources |

Year |

Emission control efficiencies (%) |

||||

|

PM |

PM10 |

PM2.5 |

SO2 |

NOx |

||

|

Huy and Oanh (2017) |

2010 |

- |

94% |

94% |

90% for all CFPPs except 2 CFPPs |

0% |

|

Roy et al. (2021) |

2019 |

- |

98.4% |

98.5% |

90% for Hai Phong 1 and 2 plant; |

30% for LNB (including all CFB) |

|

This study |

2019; 2021 |

99.2% |

- |

- |

90% for all PC CFFPs (except 2 CFPPs); 0% for CFB CFFPs |

30% for PC-CFPPs (except 7 plants of 65 -88.4%); 0% for CFB |

3. RESULTS AND DISCUSSIONS

3.1. Determination of emission factors of PM2.5 and PM10

a. Proposal of emission assessment methods for PM2.5 and PM10

In Section 2, it was noted that there is no designing treatment efficiency for PM2.5 and PM10 in Vietnam. Obtaining information about the emission of PM2.5 and PM10 in Vietnam is challenging and costly due to the sophisticated monitoring methods. However, research on PM emission in Vietnam has yielded controlled emission factors for new CFPPs and a trouble happened CFFP (Dung et al., 2014). To address the difficulties in estimating PM2.5 and PM10 in Vietnam, a method utilizing the EF of PM and the PM10/PM and PM2.5/PM ratios was proposed. The uncontrolled EF from the US.EPA-AP42 and unified emission control efficiencies of 99.2% for PM were chosen for all treatment processes, including ESP - FGD, SCR - ESP - FGD, and ESP - FGD. The size distributions of particulate matter were determined based on relevant research comparisons (Table 5).

Table 5: Particulate matter size distribution (%) in air pollution control devices (APCDs) of flue gas

|

Source |

Country |

Boiler technology/Type of coal |

APCD |

PM2.5 /PM |

PM10 /PM |

PM>10 /PM |

PM2.5/PM10 |

|

US. EPA - AP42 (1998) |

US |

PC/Bituminous -Subbituminous |

Uncontrolled |

6 |

23 |

49 |

26.09 |

|

ESP |

29 |

67 |

33 |

43.28 |

|||

|

PC/Anthracite |

Uncontrolled |

23 |

28.5 |

71.5 |

23.91 |

||

|

Baghouse |

65 |

95 |

5 |

46.15 |

|||

|

Jeong et al. (2021) |

Korea |

PC/ Bituminous - Subbituminous |

Uncontrolled |

19.4 |

54 |

46.1 |

35.93 |

|

SCR+APH+ESP |

83.1 |

93 |

7 |

89.35 |

|||

|

SCR + APH + ESP + WFGD |

86 |

95.7 |

4.3 |

89.86 |

|||

|

Wu et al. (2018) |

China |

PC/Bituminous |

Uncontrolled |

5.8 |

21.7 |

78.3 |

26.73 |

|

ESP |

34 |

69 |

31 |

49.28 |

|||

|

ESP + WFGD |

64 |

72.5 |

27.5 |

88.28 |

|||

|

CFB/Bituminous |

ESP |

32.4 |

67.6 |

32.4 |

47.95 |

||

|

Yi et al. (2008) |

China |

PC/Anthracite |

Uncontrolled |

1.7 |

16.7 |

83.3 |

10.17 |

|

Baghouse |

8.6 |

71.3 |

28.7 |

12.06 |

|||

|

Roy et al. (2021) |

Vietnam |

PC+CFB/Anthracite - Bituminous |

Controlled |

- |

- |

- |

24.46* |

|

Huy & Oanh (2017) |

Vietnam |

PC+CFB/Anthracite - Bituminous |

Controlled |

- |

- |

- |

42.34* |

Note: *The treatment efficiencies were calculated from the EFs

Table 5 shows a wide variation in the size distribution of PM of different coal types and boiler technology with different control devices. It is noted that the data for certain technologies such as PC burning of anthracite with ESP treatment is not available. The lack of size distributions also means a lack of emission factors and treatment efficiency information for PM2.5 and PM10 as data of PM are more available and the size distribution can be calculated from the emission of PM2.5 and PM10 (if available). It can be observed from Table 5 that with additional treatment devices (higher efficiency) the percentage of PM>10 reduces followed by an increase of PM10 and PM2.5. Therefore, for the current study the size distribution for particulate matter after ESP treatment of PC using bituminous coal of US.EPA - AP42 (removal percentage of 99.2% for PM) were chosen as representatives for both anthracite/bituminous coals and PC/CFB technologies. Size distribution can be upgraded in the future based on the available data.

b. Comparison of emissions based on proposal method using different PM size distributions

The calculated emissions of PM10 and PM2.5 emission of CFPPs in Vietnam based on size distribution reviewed in Section 3.1.a are presented in Table 6. We chose the size distribution in Korea of PC/ Bituminous - Subbituminous with treatment system of SCR+APH+ESP and in China of PC/Bituminous with treatment of ESP for comparison. The two options were chosen as they are the most relevant data. The treatment efficiency of the Korean system is considered higher and the treatment efficiency in China is closer to the Vietnamese condition.

The calculation results are based on size distribution US.EPA - AP42 was in the same range as those after ESP in the research in China of Wu et al. (2018) but 2.9 times lower than when calculated with the size distribution in Korea by Jeong et al. (2021) for PM2.5 and 1.3 times lower than when calculated with the size distribution in Jeong et al. (2021) for PM10. The high sensitives of PM2.5 emissions with size distribution are comparable with the high sensitivity of emission with treatment efficiency. A small change in efficiency (at a high rate) can also lead to a significant change in emission. For example, changing from the removal of 99% to 98% can lead to an increase of 100% in emissions.

Table 6: PM emissions from flue gas in CFPPs in Vietnam calculated based on different size distribution (Gg/year)

|

|

2019 |

||

|

US. EPA - AP42 (1998) (This study) |

Jeong et al. (2021) |

Wu et al. (2018) |

|

|

PM |

60.045 |

||

|

PM10 |

40.23 |

55.84 |

41.43 |

|

PM2.5 |

17.41 |

49.90 |

20.42 |

3.2. Emission of air pollutants

3.2.1. Particulate matter

Table 7 summarizes the emission of PM10 and PM2.5 from previous and current studies for the CFPPs in 2010, 2019 and forecasts for 2030. The number of CFPPs increased over time (from 12 CFPPs in 2010 to 28 CFPPs in 2019), leading to a significant increase in the amount of coal burning, increasing emissions of air pollutants (Huy and Oanh, 2017; Roy et al., 2022).

Table 7: Comparison of particulate matter inventories from CFPPs in Vietnam

|

No |

Coal consumption/Pollutants |

2010 |

2015 |

2019 |

2021 |

2030 |

|

|

Huy and Oanh (2017) |

Roy et al. (2021) |

Roy et al. (2022) |

This study |

This study |

This study * |

||

|

1 |

Coal consumption (103 tons) |

10,000 |

- |

56,625 |

53,224 |

55,150 |

- |

|

2 |

PM10 (Gg/year) |

19.3 |

12.18 |

26.47 |

40.23 |

44.27 |

61.39 |

|

3 |

PM2.5 (Gg/year) |

8.01 |

4.82 |

10.49 |

17.41 |

19.16 |

26.57 |

Note: *Projected based on PDP8

According to the results presented in Table 7, our study has revealed higher levels of PM10 and PM2.5 emissions in 2019 compared to those reported by Roy et al. (2022). It is important to note that both studies are based on local activities of CFPPs and other selected factors such as EFs, removal rate, or size distribution. Therefore, we cannot claim that our data is better. However, emissions calculated by our proposed methods can be easier updated in the future. It is also noted that corresponding with the selected PM size distribution removal efficiency in this study were 97.65% and 96.00% for PM10 and PM2.5, respectively whereas those in Roy et al. (2022) are 98.4% and 98.5%.

3.2.2. Gaseous pollutants

Table 8: Gaseous pollutants and greenhouse gases emissions from flue gas from CFPPs in Vietnam (Gg/year)

|

No. |

|

Compounds |

2010 |

2015 |

2019 |

2021 |

2030 |

||

|

Huy and Oanh (2017) |

Roy et al. (2021) |

Roy et al. (2022) |

MONRE (2022) |

This study |

This study |

This study * |

|||

|

1 |

Gaseous pollutants |

SO2 |

142 |

50.09 |

50.64 |

- |

78.48 |

78.42 |

119.76 |

|

2 |

NOx |

141 |

117.99 |

193.68 |

- |

199.21 |

188.07 |

303.97 |

|

|

3 |

CO |

11.3 |

11.58 |

23.28 |

- |

15.97 |

16.54 |

24.36 |

|

|

4 |

Greenhouse gases |

CH4 |

0.60 |

0.60 |

1.30 |

- |

1.09 |

1.10 |

1.66 |

|

5 |

N2O |

0.53 |

0.89 |

1.94 |

- |

1.63 |

1.65 |

2.49 |

|

|

6 |

CO2 |

44,776 |

58,388 |

126,058 |

106,428 |

106,808 |

108,393 |

162,978 |

|

The results of estimating gaseous pollutants (SO2, NOx, and CO) emissions of CFPPs in Vietnam are shown in Table 8. The values in 2019 are compared to evaluate our data set. The total coal consumption amount of CFPPs in this study and the study of Roy are only slightly different (this study is 6% lower). The emission of SO2 from Roy et al. 2022 is 35% lower than this study mainly because of the lower treatment efficiencies in this study, especially there are two plants with no treatment system. Besides, the conversion rate of sulfur in the coal to SO2 in flue gas (which affects emission factors) in this study is higher than that in Roy et al. (2022). The NOx emission in this study is comparable with those in Roy et al. (2022). The CO emission in this study is 31.4% lower than in Roy et al. (2022), mainly due to the use of lower emission factors and 6% lower coal consumption in this study.

Despite an increase in coal consumption, the emissions of SO2 and NOx were reduced compared to 2019. This is because of the increasing use of CFB boilers, which have lower emission factors for SO2 and NOx than PC boilers.

If the exhaust gas treatment system continues to develop at its current rate and no improvements are made, it is predicted that by 2030, most pollutants will be aproximately 1.5 times as high as those in 2019 (Table 8).

3.3. Emissions of GHGs

Table 8 displays the emissions of greenhouse gases (CH4, N2O, and CO2) from CFPPs in 2019, 2021, and projected for 2023. The calculation of greenhouse gas emissions was based on emission factors derived from the heat of burned coal. In comparison to the study conducted by Roy et al. (2022), the total heat of burned coal in this study is 19% lower. As a result, the emissions of CH4 and N2O in this study are also 19% lower than those in Roy et al. (2022), as the emission factors for these gases are similar between the two studies.

The CO2 in 2019 of this study and the number reported by the Vietnamese Ministry of Natural Resources and Environment (MONRE, 2021) are similar. Both are approximately 18% lower than the figure reported by Roy et al. (2021). This difference is primarily due to the disparity in the total heat of burned coal.

If CFPPs continue to operate without GHG emissions controls or technological advancements as outlined in PDP8, GHG emissions are projected to increase by 52.6% by 2030 compared to 2019.

4. CONCLUSIONS AND RECOMMENDATIONS

This study has calculated the emission of main air pollutants (PM2.5, PM10 …) in flue gases of CFPPs in 2019 and 2021. Three greenhouse gases (CH4, N2O, CO2) were also estimated. The projected emission of those air pollutants and greenhouse gases based on PDP8 was done for the first time.

Even though this study was based on available local data about coal consumption and coal characteristics of CFFPs, large uncertainties of the emission existed mainly because of the lack of national emission factors. Besides, the lack of information about treatment systems, design treatment efficiencies, and especially operation treatment efficiencies also increases the uncertainties of the results.

The following additional actions are recommended to reduce the uncertainties of emission inventory data of CFFPs: (1) Collection of information about air pollution treatment systems and designed treatment efficiencies of all CFFPs; (2) Determination of controlled emission factors of all CFFPs; (3) Assessment of operation treatment efficiencies of typical treatment devices in different treatment systems; (4) Surveying the technologies of boilers and coal size, consumption rates, and characteristics of additives to the boilers.

Trịnh Thị Phương Ly1, Lê Thị Thủy2, Phạm Thị Bích Thảo3

Nguyễn Thị Yến Liên4, Văn Diệu Anh1, Phùng Thị Thu Trang5, Lý Bích Thủy1,*

1School of Chemistry and Life Sciences, Hanoi University of Science and Technology

2Duc Minh Investment and Environment Development Joint Stock Company

3Independent researcher

4Faculty of Transport Safety and Environment, University of Transport and Communications

5Vietnam Institute of Meteorology, Hydrology and Climate change

(Source: The article was published on the Environment Magazine by English No. IV/2023)

REFERENCES

1. Dung, N. T., Cuong, T. D., and Hai, P. N. (2014). Emission Factors of Selected Air Pollutants of Pulverized Coal-Fired Power Plants. Journal of Sciences and Technology, 99, 022 - 026.

2. EPA. (1996). AP-42, 5th Edition Compilation of Air Pollutant Emissions Factors, Vol 1: Stationary Point and Area Sources.

3. EVN. (2018). Develop coal-fired power with high-performance, environmentally friendly technology. https://www.evn.com.vn/d6/news/Phat-trien-nhiet-dien-than-voi-cong-nghe-hieu-suat-cao-than-thien-moi-truong-6-8-21477.aspx.

4. EVN. (2019). All of EVN's thermal power facilities comply with National Technical Regulation's standards for particulate matter concentration (QCVN 22:20009/BTNMT). https://www.evn.com.vn/d6/news/Cac-nha-may-nhiet-dien-cua-EVN-deu-dap-ung-yeu-cau-ve-nong-do-bui-theo-QCVN-2220009BTNMT-6-12-24825.aspx.

5. EVN. (2019). Annual Report 2018. https://en.evn.com.vn/d6/news/Annual-Report-2021-6-13-2537.aspx

6. EVN. (2022). Annual Report 2021. https://www.evn.com.vn/userfile/User/tcdl/files/EVNAnnualReport2021%20final%2022_10_2021.pdf

7. Hien, T. T., Chi, N. D. T., Nguyen, N. T., Vinh, L. X., Takenaka, N., and Huy, D. H. (2019). Current status of fine particulate matter (PM2.5) in Vietnam’s most populous city, Ho Chi Minh City. Aerosol and Air Quality Research, 19(10), 2239–2251. https://doi.org/10.4209/aaqr.2018.12.0471.

8. Huy, L. N., and Kim Oanh, N. T. (2017). Assessment of national emissions of air pollutants and climate forcers from thermal power plants and industrial activities in Vietnam. Atmospheric Pollution Research, 8(3), 503 - 513. https://doi.org/10.1016/j.apr.2016.12.007

9. Luong, T. Van. (2018). Solution for Vietnam’s coal-fired power environment? Vietnam Energy. https://nangluongvietnam.vn/giai-phap-nao-cho-moi-truong-nhiet-dien-than-viet-nam-20302.html.

10. Ly, B. T., Matsumi, Y., Nakayama, T., Sakamoto, Y., Kajii, Y., and Nghiem, T. D. (2018). Characterizing PM2.5 in Hanoi with new high temporal resolution sensor. Aerosol and Air Quality Research, 18(9), 2487–2497. https://doi.org/10.4209/aaqr.2017.10.0435.

11. MONRE (2022). Research and determine Emission Factors of Vietnam's power grid in 2021. Department of Climate Change (DCC), Ministry of Natural Resources and Environment (MONRE). http://dcc.gov.vn/van-ban-phap-luat/1102/Nghien-cuu,-xay-dung-he-so-phat-thai-(EF)-cua-luoi-dien-Viet-Nam-nam-2021-(kèm-CV-1278/BDKH-TTBVTOD).html

12. MONRE (2013). National Environmental Status Report 2013 - Air environment.

13. Nam, N. C. (2020). Coal-fired power in the world and Vietnam: Current status - development trend. Tạp chí điện tử Công nghiệp Môi trường . https://congnghiepmoitruong.vn/nhiet-dien-than-the-gioi-va-viet-nam-hien-trang-xu-the-phat-trien-4852.html.

14. Roy, S., Lam, Y. F., Chan, J. C. L., Hung, N. T., and Fu, J. S. (2022). Evaluation of Vietnam air emissions and the impacts of revised power development plan (PDP7 rev) on spatial changes in the thermal power sector. Atmospheric Pollution Research, 13(7). https://doi.org/10.1016/j.apr.2022.101454.

15. Roy, S., Lam, Y. F., Hung, N. T., Chan, J. C. L., & Fu, J. S. (2021). Development of 2015 Vietnam emission inventory for power generation units. Atmospheric Environment, 247. https://doi.org/10.1016/j.atmosenv.2020.118042.

16. Thanh, T., Nguyen, N., Thi, N., Nhung, T., Pham Van, H., & Bui, H. Q. (2019). Current Status of PM2.5 Pollution and its Mitigation in Vietnam. https://www.researchgate.net/publication/333943305.

17. Wu, B., Tian, H., Hao, Y., Liu, S., Liu, X., Liu, W., Bai, X., Liang, W., Lin, S., Wu, Y., Shao, P., Liu, H., & Zhu, C. (2018). Effects of Wet Flue Gas Desulfurization and Wet Electrostatic Precipitators on Emission Characteristics of Particulate Matter and Its Ionic Compositions from Four 300 MW Level Ultralow Coal-Fired Power Plants. Environmental Science and Technology, 52(23), 14015 - 14026. https://doi.org/10.1021/acs.est.8b03656.

18. Yu, J. H., Song, J., Lee, D. Y., Yu, M. S., Jung, J. H., Chun, S. N., Lee, G. Y., & Kim, J. H. (2021). Comparison of PM total, PM10, PM2.5, NOx, and SO2 Emission Factors from Coal-fired Power Plants per Load Change. Asian Journal of Atmospheric Environment, 15 (3), 1-10. https://doi.org/10.5572/AJAE.2021.104.