26/07/2024

Abstract

The research on producing bioethanol from this rubber wood sawdust waste provides a method for generating green fuel from a cheap, abundant, and currently wasted resource. With the aim of improving the conversion efficiency of bioethanol from rubber wood sawdust, this study combined alkali dilute pretreatment with high pressure to facilitate easier hydrolysis of rubber wood sawdust and fermentation with Saccharomyces cerevisiae. In the study, HPLC and UV-Vis methods were used to determine the composition and content of lignin, cellulose of the raw material before and after pretreatment. Additionally, Saccharomyces cerevisiae yeast was cultured in Sabouraud dextrose Broth (SDB) medium to achieve high cell density prior to use. Simultaneous saccharification and fermentation (SSF) were conducted with appropriate temperature, time, and conditions to optimize the conversion efficiency of cellulose, hemicellulose into ethanol. The pretreatment conditions were optimized for sawdust by soaking in 2% NaOH solution for 24 hours, followed by pretreatment in a high-pressure device at 170°C (7,02 bar) for 1 hour. The results showed that sawdust after pretreatment had an increased cellulose content from 43.20% to 66.63%, with a pretreatment efficiency of 70.53%. The material subjected to pretreatment was proven to be advantageous for the fermentation process, with the resulting solution havinga bioethanol content of 1.68% vol and a conversion efficiency of 60.32% for the entire process.

Keywords: Bioethanol, Pretreatment, High Pressure, Saccharomyces cerevisiae, Lignocellulose

JEL Classification: O13, Q52, Q55

Received: 12/1/2024; Revised: 18/2/2024; Accepted: 22/6/2024

1. Introduction

The research on the bioethanol production process from lignocellulosic biomass has been carried out for decades [2][3]. However, in Vietnam, many studies on bioethanol still face challenges when transitioning to using lignocellulosic feedstock (second generation) due to various hurdles, such as issues with hydrolysis and the presence of lignin hindering enzymatic hydrolysis processes. Therefore, in the production of bioethanol from lignocellulose, the pretreatment stage is indispensable for lignin removal, improving the cellulose structure of the raw material, and creating favorable conditions for enzymatic hydrolysis. this study investigates the combined effectiveness of high-pressure conditions with diluted alkali in the pretreatment process applied to rubber wood sawdust feedstock. This research explores suitable conditions for the pretreatment process using the combined method to enhance the overall efficiency of bioethanol production.

The production of bioethanol from lignocellulosic biomass (second generation) is intensively researched due to its sustainability and abundant raw material, contributing to energy security and climate change mitigation. However, in Vietnam, transitioning to using lignocellulosic feedstock in bioethanol production faces challenges due to hydrolysis issues and lignin interference. This necessitates an efficient pretreatment stage to remove lignin, improve cellulose structure, and create favorable conditions for enzymatic hydrolysis.

This study focuses on evaluating the impact of various conditions, including concentration, treatment time with NaOH, temperature, and pressure on the cellulose structure of rubber wood sawdust. This is a crucial issue to optimize the pretreatment process, enhance bioethanol production efficiency from second-generation feedstock in Vietnam, and promote research in this field. The specific goal is to assess the effects of alkali solutions, pretreatment time, and temperature on the cellulose structure of rubber wood sawdust through parameters such as crystallinity index, porous structure, and amorphous cellulose regions, aiming to find the most suitable pretreatment method.

2. Materials and methods

2.1. Materials and chemicals

Rubber trees are perennial crops widely cultivated, with a large cultivation area in Vietnam ranking second in ASEAN and fifth globally in rubber cultivation. Every year, the rubber industry produces about 1.5 million tons of natural rubber. Following a growth cycle of 6-8 years, rubber latex is harvested. After harvesting, much of this wood is used for paper production, leaving behind rubber wood sawdust, estimated to reach millions of tons annually. This is a rich source of raw material that can meet research and application demands.

Rubber wood sawdust offers several advantages compared to other types of wood such as pine, oak, or beech. Specifically, it contains higher cellulose content (rubber wood sawdust has about 45-50% cellulose, while pine only has 40-43%, and oak ranges from 35-40%) and lower lignin content (rubber wood sawdust about 10%, while pine has around 27%, and beech about 23%). This creates favorable conditions for hydrolysis and fermentation into bioethanol [13][14].

In this experiment, the used lignocellulosic material is rubber wood sawdust from Binh Duong province, Vietnam. The sawdust, sourced from Minh Phat One Member Co., Ltd, is mechanically processed and sieved to a size smaller than 1mm, then dried and stored below 15% moisture content. Before determining the lignocellulose composition, the material is dried at 110°C until a constant weight is achieved.

Several chemicals used in the research include sodium hydroxide, potassium sodium tartrate tetrahydrate, glucose, peptone, and yeast extract (for yeast fermentation), sourced from Xilong.Saccharomyces cerevisiae, Ethanol ReD TM, is provided by the biofuel and biomass laboratory.

2.2. Analysis of composition and structure of raw materials

The composition of rubber wood sawdust is analyzed following the National Renewable Energy Laboratory (NREL) laboratory analysis procedure [8]. The sawdust is first hydrolyzed with concentrated sulfuric acid (72% w/w) for 30 minutes, followed by dilution with distilled water for a second hydrolysis step with diluted acid (4.0% w/w). The cellulose and hemicellulose components hydrolyze into glucose and xylose, respectively, and are analyzed using High-Performance Liquid Chromatography (HPLC) with a Shimadzu CTO-20A HPLC system and SUGAR SH101 column (Shimadzu HPLC analyzer, 2014). The lignin content is determined using a UV-Vis analysis instrument, specifically the NiR V770 model (Japan).

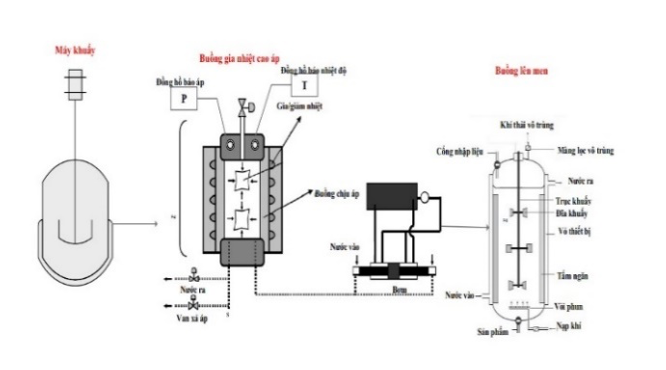

2.3. Dilute alkali pretreatment combined with high pressure investigation

Therubber wood sawdust pretreatment process was divided into two stages. In stage 1, 20g of sawdust was placed in a stirring vessel, followed by the addition of NaOH at various ratios and stirred at 120 rpm for different durations as investigated. Subsequently, the mixture was transferred to a high-pressure device for heating and pressure increase.

The experimental conditions were summarized in Table 1.

After the pretreatment process was completed, the sawdust was washed and adjusted to pH=7. Then, the fiber composition of the pretreatment-treated rubber wood sawdust was analyzed.

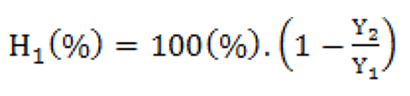

The pretreatment efficiency depended on the amount of cellulose enriched per unit of lignin and disregarded other components. This process primarily removed lignin and has little or no effect on other remaining components. The efficiency of the pretreatment process was calculated using Equation (1).

(1)

(1)

Where Y1 and Y2 represented the mass ratio of lignin/cellulose of the material before and after the pretreatment process, respectively.

Figure 1. Schematic diagram of rubber wood sawdust pretreatment using NaOH enhanced high-pressure method

2.4. Preparing yeast and culture medium

Before fermentation, the Saccharomyces cerevisiae yeast strain Ethanol ReD TM was activated in Sabouraud dextrose Broth (SDB) liquid medium, sterilized at 121°C for 10 minutes. The yeast inoculation process took place in a shaking incubator (120 rpm, 35°C, for 48 hours). The yeast density was measured using optical density (OD) at a wavelength of 610nm using a UV-Vis Hach DR 5000 device.

2.5. Simultaneous Enzymatic Hydrolysis and Fermentation

The rubber wood sawdust after treatment was loaded into a 250 mL Erlenmeyer flask, supplemented with water at a solid/liquid ratio of 1/10 and 2.0% peptone. The mixture was then heated to 121°C for 10 minutes and cooled down to 35°C. Subsequently, 5.0% vol of Saccharomyces cerevisiae yeast and 5.0%vol of Acremonium Cellulase enzyme (from Meiji Seika) with an activity of 100 IU/mL are added. The fermentation medium was maintained in a shaking incubator at 35°C and 120 rpm throughout the Simultaneous Saccharification and Fermentation (SSF) process. The reaction flasks were tightly sealed to prevent CO2 from escaping and to prevent contamination of the fermentation medium by other microorganisms.

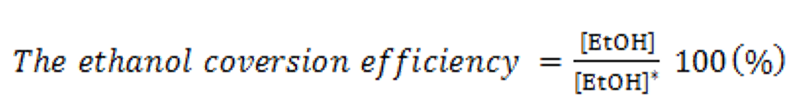

The ethanol conversion efficiency was calculated based on the theoretical amount of ethanol converted from the cellulose of the initial rubber wood ([EtOH]* was 2.785% volume ethanol in this study) using the following equation (2):

(2)

(2)

Where [EtOH] was the maximum concentration of ethanol producedduring the fermentation process(volume).

3. Results and discussion

3.1. Results of raw material composition and structure analysis

The analysis results show that the main components include cellulose (43.20%), hemicellulose (21.22%), lignin (20.56%), ash (3.42%), and other components (11.63%). The high cellulose content indicates the potential for converting rubber wood into bioethanol. From the component results, the lignin/cellulose ratio can be calculated as 0.48. This ratio indicates that the lignin content in rubber wood is significant, almost half of the cellulose content. It is necessary to remove lignin before proceeding with hydrolysis and ethanol fermentation.

3.2. Investigation of concentration and time in stage 1: NaOH pretreatment

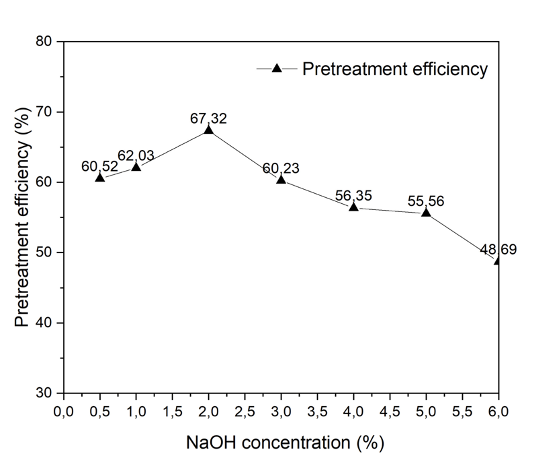

This study has provided new insights into the influence of NaOH concentration and time in the alkali pretreatment process on the efficiency of pretreatment for rubber wood sawdust.

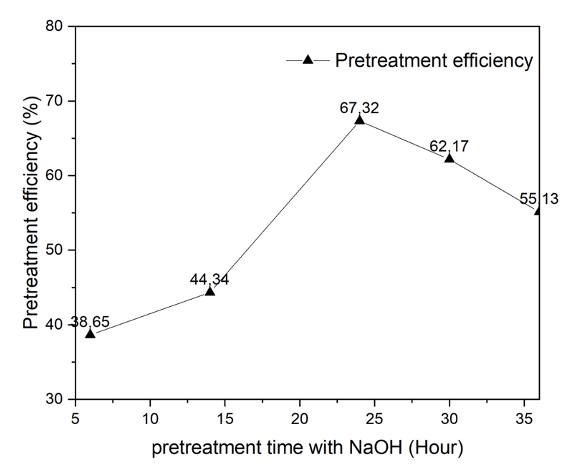

From the results in Figure 2 and Table 1, it can be observed that the effect of NaOH concentration shows an increase in pretreatment efficiency from 60.56% to 67.32% when increasing the concentration from 0.5% to 2%. This is because NaOH has a stronger effect in lignin removal and reducing the crystallinity of cellulose. However, when the NaOH concentration is further increased to 6%, the pretreatment efficiency decreases to 48.69%. This could be due to the high NaOH concentration causing significant loss of carbohydrates, leading to the loss of small cellulose and hemicellulose fibersduring processing and washing.

Figure 2. Experimental investigation of the influence of NaOH concentration inthe pretreatment process

Figure 3. Experimental investigation of the influence of NaOH pretreatment time

The results regarding excessively high NaOH concentrations leading to carbohydrate loss align well with the findings from reference [9], which suggest that lignin removal using alkali can reduce efficiency due to the loss of cellulose and hemicellulose fibers.

Additionally, previous studies have also indicated that overly strong pretreatment conditions such as high temperature, high alkali concentrations, or prolonged processing times can lead to significant losses in valuable carbohydrate components in the feedstock [10]. Therefore, it is necessary to optimize the pretreatment conditions to achieve the highest efficiency possible.

Table 1. Experimental conditions and component analysis results

|

The univariate effects |

NaOH concentration(%) |

Chemical pretreatment time (h) |

High-pressure temperature(°C) |

High-pressure time (h) |

Pressure (bar) |

Cellulose |

Hemicellulose |

Lignin |

Ash |

Remaining substances |

Y2: Lignin/ cellulose |

|

|

NaOHconcentration |

0,5 |

24 |

150 |

1 |

3,45 |

55,86 |

14,52 |

10,50 |

4,07 |

15,06 |

0,188 |

|

|

1 |

24 |

150 |

1 |

3,43 |

56,47 |

14,12 |

10,20 |

5,03 |

14,18 |

0,181 |

||

|

2,0 |

24 |

150 |

1 |

3,38 |

61,40 |

15,35 |

9,55 |

4,30 |

9,40 |

0,156 |

||

|

3,0 |

24 |

150 |

1 |

3,45 |

50,32 |

12,58 |

9,52 |

3,52 |

24,05 |

0,189 |

||

|

4,0 |

24 |

150 |

1 |

3,48 |

46,52 |

11,63 |

9,67 |

3,26 |

28,92 |

0,208 |

||

|

5,0 |

24 |

150 |

1 |

3,49 |

44,95 |

11,24 |

9,51 |

6,74 |

27,56 |

0,212 |

||

|

6,0 |

24 |

150 |

1 |

3,54 |

39,17 |

9,79 |

9,57 |

8,62 |

32,85 |

0,244 |

||

|

Chemical pretreatment time |

2 |

6 |

150 |

1 |

3,59 |

49,07 |

12,27 |

14,33 |

5,89 |

18,45 |

0,292 |

|

|

2 |

14 |

150 |

1 |

3,46 |

45,19 |

11,30 |

11,97 |

5,42 |

26,12 |

0,265 |

||

|

2 |

24 |

150 |

1 |

3,38 |

61,40 |

15,35 |

9,55 |

4,30 |

9,40 |

0,156 |

||

|

2 |

30 |

150 |

1 |

3,42 |

59,03 |

14,76 |

10,63 |

6,13 |

9,46 |

0,180 |

||

|

2 |

36 |

150 |

1 |

3,51 |

44,85 |

11,21 |

9,58 |

6,73 |

27,63 |

0,214 |

||

|

High-pressure temperature |

2 |

24 |

150 |

1 |

3,39 |

60,38 |

15,10 |

9,55 |

4,23 |

10,74 |

0,158 |

|

|

2 |

24 |

170 |

1 |

7,02 |

66,63 |

14,66 |

9,35 |

4,66 |

4,70 |

0,140 |

||

|

2 |

24 |

190 |

1 |

12,22 |

63,38 |

14,58 |

9,56 |

4,44 |

8,05 |

0,151 |

||

|

2 |

24 |

210 |

1 |

17,83 |

61,91 |

12,38 |

9,55 |

4,33 |

11,82 |

0,154 |

||

|

2 |

24 |

230 |

1 |

19,87 |

60,34 |

9,05 |

9,55 |

4,22 |

16,83 |

0,158 |

||

|

High-pressure time |

2 |

24 |

170 |

0,5 |

7,09 |

60,76 |

15,19 |

9,55 |

4,25 |

10,24 |

0,157 |

|

|

2 |

24 |

170 |

1 |

7,02 |

66,63 |

14,66 |

9,35 |

4,66 |

4,70 |

0,140 |

||

|

2 |

24 |

170 |

2 |

7,03 |

65,08 |

16,27 |

9,56 |

4,56 |

4,54 |

0,147 |

||

|

2 |

24 |

170 |

3 |

7,06 |

63,40 |

15,85 |

9,56 |

4,44 |

6,74 |

0,151 |

||

|

2 |

24 |

170 |

4 |

7,06 |

62,73 |

15,68 |

9,56 |

4,39 |

7,63 |

0,152 |

||

3.3.Study the temperature and time conditions for stage 2: High-pressure pretreatment

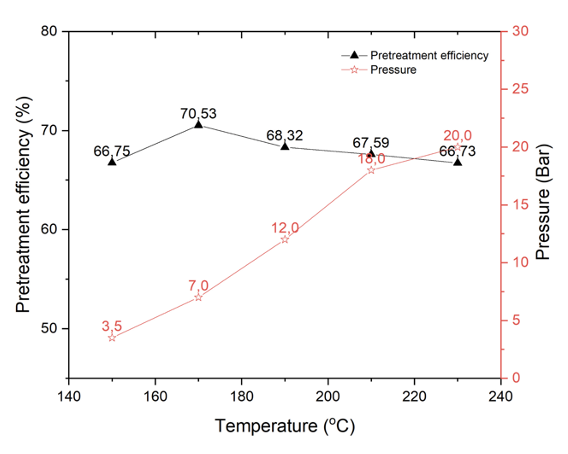

To enhance the efficiency of the process, this study has introduced a novel finding regarding the application of high-pressure methods to improve the efficiency of alkali pretreatment of rubber wood sawdust for bioethanol production. The results indicate that combining soaking the raw material in a 2% NaOH solution for 24 hours (stage 1) and subsequently conducting pretreatment at 170°C and 7.02 bar pressure for 1 hour (stage 2) resulted in the highest pretreatment efficiency of 70.53%.

Figure 4. Experiment investigating the influence of high-pressure temperature on the efficiency of high-pressure pretreatment

The results from Figure 4 show that increasing the temperature and pressure to certain levels (170°C, 7.02 bar) enhances the pretreatment efficiency by promoting molecular oscillation and increasing lignin solubility. However, when the temperature and pressure are too high (230°C, ~20 bar), the efficiency decreases due to increased thermal hydrolysis of hemicellulose, cellulose, and lignin degradation.

The optimalhigh-pressurepretreatment time recorded in this study is 1 hour, as longer times reduce efficiency and consume more energy.

The use of NaOH as an alkali treatment agent in stage 1 aligns with previous studies suggesting that alkalis can remove lignin and enhance enzyme access to cellulose [4][5].

Furthermore, the concept of combining alkali soaking with increased temperature and pressure to enhance pretreatment efficiency has also been applied in other studies on different lignocellulosic materials. For example, Kumar et al. (2009) [11] studied straw, and Allan Zhong (2016) [12] researched rubber wood.

3.4. Evaluation of simultaneous saccharification and fermentation process (SSF)

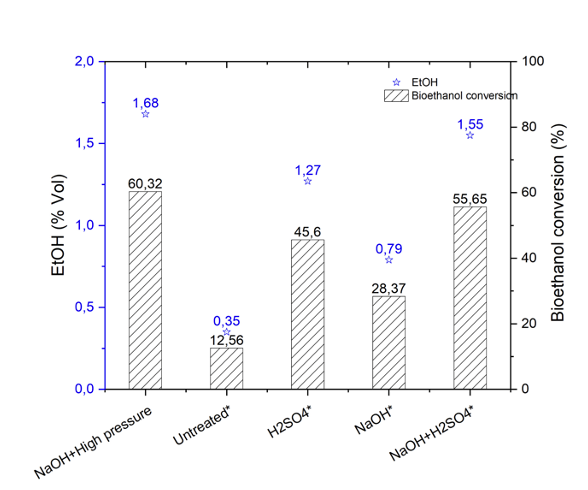

Figure 5. SSF fermentation results of TXL samples with different methods (Results from the experiment by Le Tan Nhan Tu and colleagues (2020) [10]).

The results demonstrate that enhancing high-pressure conditions for the alkali pretreatment process with NaOH (as described in Sections 3.2 and 3.3) yielded the highest ethanol yield of 1.67% vol with a bioethanol conversion rate of 60.32%. The improved pretreatment efficiency increased the enzymatic hydrolysis efficiency by increasing cellulose content and significantly reducing lignin content. The reduction in lignin content enhanced the enzymatic hydrolysis efficiency.

Comparing these results with the fermentation of rubber wood sawdust from the study by Le Tan Nhan Tu et al. (2020), where treatment with only acid yielded 0.79% vol ethanol and treatment with only alkali yielded 1.27% vol, with bioethanol conversion rates of 28.51% and 45.62%, respectively. The combined acid-alkali approach also resulted in an ethanol concentration of only 1.55% vol (with an efficiency of 55.65%) [10].

These findings highlight the significant importance of enhancing high-pressure conditions for the alkali pretreatment process with NaOH to promote enzymatic hydrolysis and simultaneous saccharification and fermentation (SSF) by rapidly removing a substantial amount of lignin and loosening the structure of rubber wood sawdust.

4. Conclusion

This study has highlighted the importance of the pretreatment step in the conversion process of rubber wood sawdust into bioethanol and the effectiveness of applying high-pressure methods to enhance the pretreatment process. The optimal conditions consist of two stages: (1) Soaking the raw material in 2% NaOH for 24 hours and (2) Pretreatment at 170°C and 7.02 bar for 1 hour, achieving the highest efficiency of 70.53%. These results outperform previous pretreatment methods, demonstrating the positive impact of combining alkali soaking with increased temperature and pressure.

Despite achieving high efficiency, the study still faces certain limitations. The use of high-pressure conditions requires specialized equipment and higher energy costs compared to conventional methods. Building upon this research, future studies can focus on optimizing the entire bioethanol production process from rubber wood sawdust, combining optimal pretreatment conditions with other factors such as selecting yeast strains, fermentation conditions, etc. Additionally, further research on the application of high-pressure methods for pretreatment of other lignocellulosic materials is also a worthwhile direction.This research could provide a quality solution for the bioethanol production industry in Vietnam, promoting sustainable energy and contributing to environmental pollution reduction and energy security in the country.

Acknowledgement: The authors would like to express their gratitude for the time and facilities support provided by Ho Chi Minh City University of Technology (HCMUT), VNU-HCM for this research. This study was funded by Ho Chi Minh City University of Technology, VNU-HCM under the project code SVKSTN-2023-KTHH-03. We would like to thank Ho Chi Minh City University of Technology, VNU-HCM for their support in this research.

Ngô Trần Bảo Việt1,2, Huỳnh Nguyễn Đức Tài1,2,

Trần Thanh Toàn1,2, Lê Nguyễn Phúc Thiên1,2, Nguyễn Đình Quân1, 2, *

1Biomass Lab, Department of Chemical Engineering, Ho Chi Minh City University of Technology, Vietnam.

2Ho Chi Minh City National University.

(Source: The article was published on the Environment Magazine by English No. II/2024)

REFERENCES

1.H. My, “Realizing Vietnam's Commitments on Zero-Carbon Economy at COP26 Conference,” Vietnam Financial Times, 2022, [Online]. Available: https://thoibaotaichinhvietnam.vn/hien-thuc-hoa-cac-cam-ket-cua-viet-nam-ve-kinh-te-zero-carbon-tai-hoi-nghi-cop26-109588.html. [Accessed: 17-Jan-2024].

2. S. Larsson et al., “The generation of fermentation inhibitors during dilute acid hydrolysis of softwood,” Enzyme Microb. Technol., vol. 24, no. 3–4, pp. 151–159, Feb. 1999.

3. M. A. Cotta, “Ethanol production from lignocellulosic biomass by recombinant Escherichia coli strain FBR5,” Bioengineered, vol. 3, no. 4, pp. 197–202, Jul. 2012.

4. F. Vargas, E. Domínguez, C. Vila, A. Rodríguez, and G. Garrote, “Agricultural residue valorization using a hydrothermal process for second generation bioethanol and oligosaccharides production,” Bioresour. Technol., vol. 191, pp. 263–270, Sep. 2015.

5. J. K. Xu and R. C. Sun, “Recent Advances in Alkaline Pretreatment of Lignocellulosic Biomass,”In Elsevier eBooks (pp. 431–459). 2016.

6. A. Mittal, R. Katahira, M. E. Himmel, and D. K. Johnson, “Effects of alkaline or liquid-ammonia treatment on crystalline cellulose: Changes in crystalline structure and effects on enzymatic digestibility,” Biotechnol. Biofuels, vol. 4, no. 1, pp. 1–16, Oct. 2011.

7. P. Binod et al., “High temperature pretreatment and hydrolysis of cotton stalk for producing sugars for bioethanol production,” Fuel, vol. 92, no. 1, pp. 340–345, Feb. 2012.

8. A. Sluiter et al., “Determination of Structural Carbohydrates and Lignin in Biomass Laboratory Analytical Procedure (LAP) Issue Date: 7/17/2005,” 2008.

9. F. F. De Menezes et al., “Alkaline Pretreatment Severity Leads to Different Lignin Applications in Sugar Cane Biorefineries,” ACS Sustain. Chem. Eng., vol. 5, no. 7, pp. 5702–5712, Jul. 2017.

10. N. T. Le Tan, Q. P. Dam, T. P. Mai, and D. Q. Nguyen, “The Combination of Acidic and Alkaline Pretreatment for a Lignocellulose Material in Simultaneous Saccharification and Fermentation (SSF) Process,” Chem. Eng. Trans., vol. 89, pp. 43–48, Dec. 2021.

11. Kumar, P., Barrett, D. M., Delwiche, M. J., & Stroeve, P. (2009). Methods for pretreatment of lignocellulosic biomass for efficient hydrolysis and biofuel production. Industrial & Engineering Chemistry Research, 48(8), 3713–3729. https://doi.org/10.1021/ie801542g.

12. Zhong, A. (2016). Challenges for High-Pressure High-Temperature applications of rubber materials in the oil and gas industry. In Conference proceedings of the Society for Experimental Mechanics (pp. 65–79). https://doi.org/10.1007/978-3-319-21765-9_10.

13. Klash, A., Ncube, E., du Toit, B., & Meincken, M. (2010).

14. Determination of the cellulose and lignin content on wood fibre surfaces of eucalypts as a function of genotype and site. European journal of forest research, 129(4), 741–748.