18/09/2023

Abstract:

After more than 350 years since the first steam-powered vehicle was invented in 1672, much has been changed in the automotive industry towards sustainable and environmentally friendly products. Nowadays, the development of a circular economy (CE) in the automotive industry has attracted the attention of many countries. The main objective of study is to understand how to approach sustainable products in the automotive industry and adapt to social needs. Through analysis and synthesis methods, the study analyzed international car manufacturers' experience in developing sustainable products. The results indicate that there is a trend of switching to electric vehicles in the policies of international car manufacturers, while car manufacturers also set policies and regulations in accessing sustainable products for the development of CE.

Keywords: Automotive industry; sustainable development; circular economy.

JEL classification: F64, K32, Q01, Q56.

Received: 05 May 2023; Revised: 07 June 2023; Accepted: 24 July 2023.

1. Introduction

Based on the naturally evolving needs of the automotive industry, the transition products powered by internal combustion engines are being replaced and towards electric vehicles (EVs). Strict vehicle efficiency and/or CO2 standards have driven electric vehicle (EV) adoption in most of the leading EV markets. Countries are looking to accelerate the transition to EVs. In the 2022 report on EVs by the International Energy Agency (IEA), the average CO2 emissions generated during the production of battery EVs was 5.4 tons. In terms of legislation, zero-emission vehicle policy and goals are enacted by many countries, for example: An executive order in the United States in August 2021 sets new ambitions for EVs, which will account for 50% of sales of light vehicles (LDVs) by 2030; or in October 2021, an announcement of an ambition to achieve 100% zero-emission LDV sales by 2035 in Chile. Additionally, in Canada, a new target is to achieve 100% zero-emission LDV sales by 2035 instead of 2040. New interim targets for 20% zero-emission LDV sales by 2026, vision reaching 60% by 2030 has also been set.

The relationship between the automotive industry and the supply of raw materials is one of the main challenges and obstacles (Buruzs and Torma, 2017). Lithium-ion batteries are a common source of power for clean technologies such as EVs. These batteries are a key part of current efforts to replace gas-powered cars that emit CO2 and other greenhouse gases. In recent research by the Massachusetts Institute of Technology (MIT), the emissions generated during the production of the 80kWh lithium-ion battery found in the Tesla Model 3. In Europe, more than 12 million light vehicles plus 1 million heavy and off-road vehicles (HDORs) reach the end of their life each year (Michael et al., 2018). The European Union is working to meet carbon emissions reduction targets as part of the Fit for 55 in 2030 package. Remanufactured parts have up to 80% less new materials and up to 50% less CO2 emissions to produce than a new part, which is great for sustainability, affordability and customer choice.

Overall, EVs remain the key technology to decarbonize road transport with around 16% of global emissions. Therefore, Government spending on electric car subsidies is inevitable. In China, the electric vehicle (EV) industry subsidy program until the end of 2022 (from the previous expiration date in 2020) is extended. The purchase tax exemption policies for EVs continue until the end of 2023. In Japan, after doubling the subsidy amount in December 2020, the Japanese Government announced a budget allocation of 25 billion JPY (approximately US$ 230 million) for Zero Emissions Vehicle (ZEV) grants.

2. Data collection

Many previous studies are related to the approach to sustainable products for the CE development of the automotive industry. For example, the research by Martin et al. (2019) aims to identify the drivers and barriers to the implementation of a CE in the automotive industry of Pakistan. This research found that “profitability/market share/benefits” (30%), “cost reduction” (22%) and “business principles/environmental concerns/valuation high prices” (19%) were the top three drivers. Similarly, “ignorance” (22%), “cost and financial constraints” (20%) and “lack of expertise” (17%) are the top three barriers to implementing CE principles in the Pakistani automotive industry.

Another research by Gonzalo et al. (2020) shows that ecological innovation in products, processes and management has a significant positive impact on the CE of companies in the automotive industry. Research by Schulz's (2021) analyzes the electric vehicle battery case at a German car manufacturer to explore the decision context for the CE. In particular, the factors that need to be developed related to the development of the CE in the automotive industry include Transparency, planning ability, integration process in product development and business culture. Or research by Simone Wurster (2021) provides a method to support the development of CE products, in which the application of software meets the global demand for more sustainable automotive tire products.

In addition, the research of Eleni et al. (2021) has clarified the reality of the application of CE models in production that allows the transformation from the “take-to-do” linear model to closed-loop economic models that reduce waste production. Establishing DigiPrime's KPI framework for the CE transition is critical to driving performance metrics across the automotive value chain. Research by Anne et al. (2022) finds that the transition to recycled plastics in the automotive industry requires a network of solutions that together create systemic change.

Recently, research by Syed, Saurabh and Qasim (2023) assesses the tendency of automakers to prioritize waste reduction, product management and asset analysis. It is essential to develop new strategies and aspects related to machine tools through Industry 4.0 (I4.0). Through collected data statistically analyzed from 98 manufacturers and 296 end users, perceived factors affecting operational performance for the automotive industry CE-oriented in India. Research by Halia and Rayyan (2023) focuses on analyzing the automotive industry in the I4.0 based on the energy and fuel issues of cars, towards electric vehicles. Based on an analysis of initiatives undertaken by the top 10 auto companies in the Fortune 500 List, the automotive industry must incorporate circularity in the transition to EVs, and I4.0 is seen as key motivators and facilitators. I4.0 includes biotechnology, materials technology, digitization state and information technology applications intelligence. Thereby proposing a method of implementing sustainable production through 2 levels for the entire life cycle of automobiles.

3. Sustainable products approach in the automotive industry

The CE offers a solution to integrate sustainability across the automotive industry life cycle. In addition to the goal of minimizing emissions in manufacturing operations, adopting a sustainable products approach in the automotive industry will allow manufacturers to significantly improve profitability.

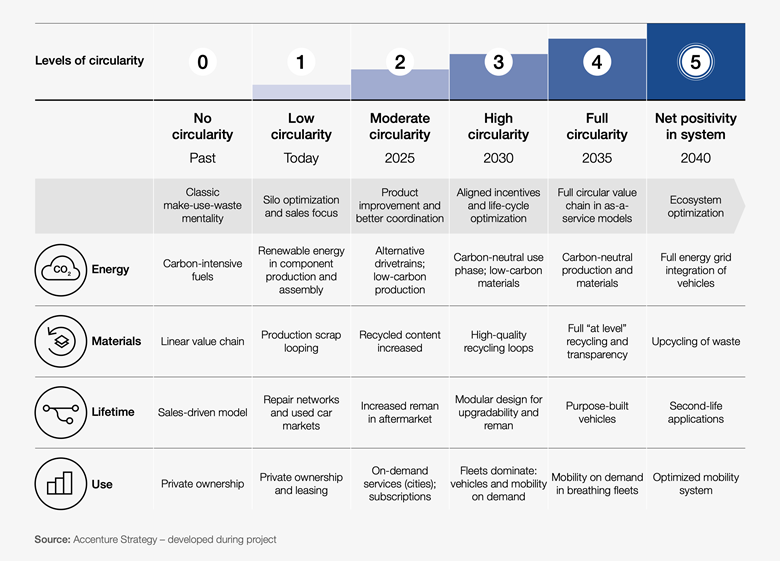

Figure 1. Plan for the development of CE in the automotive industry in phases

(Source: Accenture Strategy, 2023)

Car manufacturers are aiming to create decarbonizing vehicles for the green environment. During subsequent operation and depending on their power source, electric vehicles can offset the higher CO2 emissions that initially occurred during production. If one could only operate an electric vehicle using renewable energy sources, the CO2 emissions compared with vehicles using an internal combustion engine would be reduced by up to 70% over its life cycle. To do this, setting environmental standards is highly recommended. Regulations require manufacturers to make vehicles lighter to be more energy efficient. The focus in the design phase is on making vehicles energy efficient, for example using lightweight materials such as plastic during service life, shifting the burden to the end of the life cycle where they must be recycled.

One of the ways to approach a sustainable product is to recycle automotive parts. Most countries in the EU have laid out plans for the automotive industry in Directive 2000/53/EC towards a CE by 2050, ELV Directive No. 2000/53/EC setting out the principled end-of-life management of light vehicles. Specifically, the directive establishes a minimum reuse and recycling rate of 85% of the vehicle's total weight and a minimum reuse and recovery rate of 95% of the total weight. In the EU, the tire production process is promoted under the objective of CE. Combination of promoting the development of tire wear and mileage testing procedures, stimulating tire labeling and CE certification, and implementing media and advertising of high-quality tires Low PAH. The main source of PAH emissions comes from exhaust fumes of fuel-using engines. When PAH is distributed in a wide range, there is a significant number of PAHs with high carcinogenic potential. With the wave created several other countries such as Japan, Korea, India and many US state governments have also introduced regulations on the requirements for recycling electric vehicle parts at the end of their life.

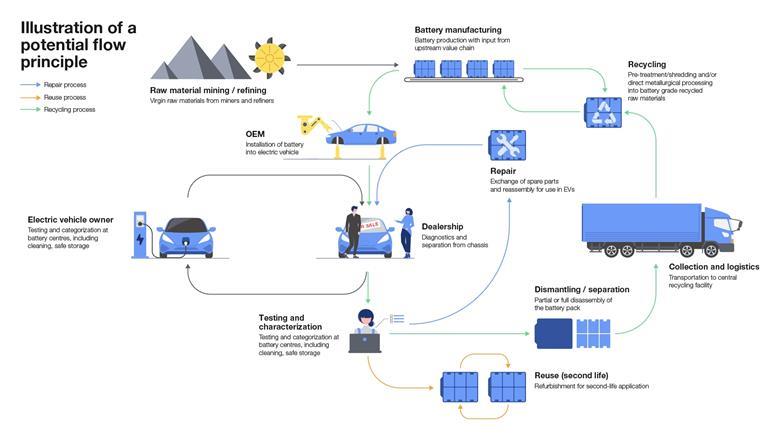

Figure 2. Battery circular value chain

(Source: Wo rld Economic Forum, 2022)

Recycling batteries provides to produce materials and is guaranteed to be environmentally friendly. To develop sustainable products, a linear to cyclical lifecycle transition in the automotive industry.

Figure 3. Value hill target picture - circularity and service-driven business model for automotive

(Source: Sebastian, et al., 2023)

Material circulation and life optimization can be achieved through reuse, remanufacturing and refurbishment. In which, there are 3 approaches: (1) Design parts using materials that are easy to disassemble, recover and recycle at the end of the first life cycle; (2) Recycle the production scrap and return the waste material to the production loop; (3) Remanufactured defective parts.

4. Experience of famous car manufacturers in the world on CE development

In 2021, several major automakers have announced their ambitions to achieve an all-electric future.

Table 1. Electric vehicle product development plan of international car manufacturers

|

Automaker |

Announcement date |

Ambition |

|

|

Toyota |

2021 |

3.5 million annual electric car sales by 2030 and the rollout of 30 BEV models. |

|

|

Volkswagen |

2021 |

All-electric vehicles to exceed 70% of European and 50% of Chinese and US sales by 2030, and by 2040 nearly 100% to be ZEVs. |

|

|

Ford |

2021 |

One-third of sales to be fully electric by 2026 and 50% by 2030, with all-electric sales in Europe by 2030. |

|

|

BMW |

2021 |

50% of vehicles sold to be fully electric by 2030 or earlier. |

|

|

Volvo |

2021 |

Become a fully electric car company by 2030. |

|

|

Geely |

2021 |

20% of car sales to be electric by 2025. |

|

|

Mercedes-Benz |

2021 |

All newly launched vehicles will be fully electric from 2025. |

|

|

General Motors |

2022 |

30 EV models and BEV production capacity of 1 million units in North America by 2025, plus carbon neutrality in 2040. |

|

(Source: International Energy Agency (IEA), 2022)

Famous car manufacturers in the world have built principles in applying corporate social responsibility in their operations. Specifically, the levels of deployment of electric vehicles by international automakers for the CE are divided into four levels: At level 1, activities are geared towards reuse, refurbishment, and repair. At level 2, the implementation focuses on Remanufacturing and repurpose. At level 3, Recycling activities contribute to the development of the CE. At level 4, the operating process is mainly about Waste management and recovery residual management.

Table 2. Summary of the trend of switching to electric cars of international car manufacturers

|

Auto Company |

Shifting to EV's |

Goals |

Circularity |

|

Toyota Motors |

Yes |

30 battery EV models by 2030. |

All 4 levels: Yes |

|

Volkswagen |

Yes |

Fleet electrified: 50% by 2030 and 100% by 2040. |

All 4 levels: Yes |

|

Daimler (Mercedes-Benz) |

Yes |

2025 onwards all new vehicle architectures will be electric-only, with an all-electric alternative for every model the company makes. |

All 4 levels: Yes |

|

Ford Motor |

Yes |

100% passenger vehicles EV in Europe 2030; 40–50% EV Mix (battery-electric, fuel cell, and plug-in hybrid vehicles) by 2030. |

Level 1: No Level 2,3,4: Yes |

|

Honda Motor |

Yes |

100% zero-emissions sales by 2040. |

Level 1,2: No Level 3,4: Yes |

|

General Motors |

Yes |

Thirty new global EV launches planned through 2025, 40–50% EV Mix (battery-electric, fuel cell, and plug-in hybrid vehicles) by 2030. |

Level 1: No Level 2,3,4: Yes |

|

BMW Group |

Yes |

All future new models from BMW will be fully electric, MINI exclusively all-electric by early 2030s, Rolls-Royce all-electric brand cars from 2030 onwards. |

All 4 levels: Yes |

|

SAIC Motors |

Yes |

100 new energy models with its partners by 2025 (includes battery electric vehicles as well as plug-in hybrid and hydrogen fuel cell vehicles). |

All 4 levels: Yes |

|

China FAW Group |

Yes |

Partnering with Audi to build EVs in China. |

Level 1: No Level 2,3,4: Yes |

|

Hyundai Motor |

Yes |

Offer ten electrified, eco-focused vehicles by the end of 2022. |

Level 1: No Level 2,3,4: Yes |

(Source: Halia & Rayyan, 2023)

Toyota is an international car brand from Japan, established in 1937. In the corporate sustainability report, the company focuses on enhancing our long-standing 360-degree approach to 4R, including: Reduce, Reuse, Recycle and Recover. Along with that, Toyota set out the Toyota Environmental Challenge 2050 strategy, the Carbon Neutrality plan of the Toyota vehicle life cycle assessments. For example, Austria's new parts depot is carbon neutral by design [1], Zero-carbon ventilation systems for new plant operations [2], Decarbonizing our logistics activities in Europe [3], Our journey to a zero CO2 paint shop [4], Hybrid demand drives transformation of Toyota in Poland [5], TME installs a wind turbine and solar panels at HO [6], In pursuit of Zero Purchased Industrial Water [7]... Besides, battery recycling activities provide for the material production process are also implemented by Toyota. More than 200 hybrid batteries recycled from Toyota Camry vehicles are being used as part of a renewable energy project in Yellowstone (Japan). At the same time, Ten batteries from the Prius cars are grouped together to store locally produced electricity from photovoltaic panels.

Volkswagen is an international car brand from Germany, established in 1937. Today, the Company reuses waste from production, logistics, workshops and technical development to produce high-quality materials. By 2050, the entire Volkswagen Group will be a CO2-neutral company and around 70 new all-electric car models will be launched across the group by 2028. Volkswagen customers can actively purchase used and tested genuine spare parts, especially engines, transmissions and airbags, such as Takata airbag recall campaign [8]. In addition, related electronic devices containing valuable raw materials are also remanufactured in accordance with Volkswagen policy.

BMW is an international car brand from Germany, established in 1916. The Company establishes a specific policy in the reuse of auxiliary materials, specifically up to 50% in cast aluminum components; 25% in steel structures and 20% in thermoplastics. The BMW Group implements many corporate development policies towards a CE. In Indonesia, the Company, together with tire manufacturer Pirelli, launched the “Living Rubber” initiative, advocating for the long-term non-deforestation of natural rubber. Or in Chile, the BMW Group joined the interdisciplinary project “Responsible Lithium Partner” in 2022 by sharing scientific findings on the impact of lithium mining on water resources in the region [9].

Daimler AG is an international car brand from Germany, established in 1926, later merging the brands and officially becoming Mercedes-Benz Group in 2022. In recent years, the Company has focused on net carbon-neutral vehicle manufacturing activities. Many measures to enhance environmental protection and resource conservation are typical for the plant such as: the photovoltaic system on the roof of the hall meets about 30% of the annual electricity demand [10]. In addition, the business has specialized Mercedes-Benz used spare parts centers. The activity of these centers is to sell parts that are disassembled, recovered for recycling and reused-used tires can be reused as composites in road construction. At the same time, build a new digital system - OMNI plus ON. This eShop system can be used to order all spare parts and components online and put them through a rigorous remanufacturing cycle. As part of the “Ambition 2039” vision, Mercedes-Benz's goal for its passenger cars is to deliver a new fleet of vehicles with zero net carbon over the next 20 years [11].

Mazda is an international car brand from Japan, established in 1931. In corporate development strategy report, Mazda aims to ensure carbon neutrality in its entire business by 2035, with a vision to 2050, the Company focuses on three aspects: (1) energy conservation, (2) transition to renewable energy and (3) development of carbon-neutral fuels for indoor transportation. Based on cooperation with suppliers and dealers, Mazda has established a system to promote sustainability initiatives throughout the entire value chain [12]. The move towards sustainable products is being taken seriously by the Company. Currently, Mazda processes waste from automobile shredders (ASR), chlorofluorocarbons and air bags. Recycling policy for end-of-life automotive products is followed. Mazda connects with businesses in the disposal of products from the end owner and transfers them to companies. In addition, the Company is preparing for the development of new technologies and measures to promote recycling programs.

5. Conclusion

The plans and policies to deploy electric vehicles are one of the orientations to approach sustainable products for the CE development of international car manufacturers. Besides, many related aspects are also taken into account such as recycling of auto parts (tires, airbags), battery recycling, and replacement of renewable energy sources. This is about balancing the 3Ps: People, Planet, and Profits.

“CE is a team sport”. It seems that no company implements the CE in isolation, the model approach in practice requires international car manufacturers to make policies in product design, business models, more comprehensive activities and partnerships in the future.

Nguyễn Hoàng Nam1,2,3

1Faculty of Law, College of Economics, Law and Government, University of Economics Ho Chi Minh City (UEH)

2Institute of Business Research (IBR), UEH

3Nong Lam University

(Source: The article was published on the Environment Magazine by English No. II/2023)

References

1. Agyemang, M., Kusi-Sarpong, S., Khan, S.A., Mani, V., Rehman, S.T. and Kusi-Sarpong, H. (2019), “Drivers and barriers to CE implementation: An explorative study in Pakistan’s automobile industry”, Management Decision, Vol.57 No.4, pp.971-994. DOI: https://doi.org/10.1108/MD-11-2018-1178.

2. Anne, R. V. B., Michelle, Z., Michiel C. Z. and Leo, P. (2022), “Solution-focused sustainability assessments for the transition to the CE: The case of plastics in the automotive industry”, Journal of Cleaner Production, Vol.358, pp.1-12. DOI: https://doi.org/10.1016/j.jclepro.2022.131606.

3. Accenture Strategy (2023), Addressing macroeconomic challenges in the automotive industry. Available at https://www.accenture.com/us-en/industries/automotive-index.

4. Buruzs, A. and Torma, A. (2017), “A Review on the Outlook of the CE in the Automotive Industry”, International Journal of Environmental and Ecological Engineering, Vol.11, No.6, pp.576 - 580. DOI: https://doi.org/10.5281/zenodo.1316081.

5. Eleni, K., Alexakis, K., Kapsalis, P., Kokkinakos, P. and Askounis, D. (2021), “The DigiPrime KPIs’ framework for a CE transition in the automotive industry”, Procedia Manufacturing, Vol.54, pp.302 - 307. DOI: https://doi.org/10.1016/j.promfg.2021.09.003.

6. Halia, M. V. M. and Rayyan H. C. (2023), “Automotive industry's circularity applications and industry 4.0”, Environmental Challenges, Vol.12, DOI: https://doi.org/10.1016/j.envc.2023.100725.

7. Laura, C. A. E., Akshat, K., Michael, S. K., Kim, H. C. and Gregory, A. K. (2020), “CE framework for automobiles: Closing energy and material loops”, Journal of Industrial Ecology, Vol.25, Iss.4, pp.877 - 889.

8. Michael, S., Bernard, Y., Yann, L. and Francois, C. (2018), “Heavy vehicles on the road towards the CE: Analysis and comparison with the automotive industry”, Resources, Conservation and Recycling, Vol.135, pp.108-122. DOI: https://doi.org/10.1016/j.resconrec.2017.06.017.

9. Maldonado-Guzmán, G., Garza-Reyes, J.A. and Pinzón-Castro, Y. (2021), “Eco-innovation and the CE in the automotive industry”, Benchmarking: An International Journal, Vol.28, No.2, pp.621 - 635. https://doi.org/10.1108/BIJ-06-2020-0317.

10. Schulz, M., Niero, M., Rehmann, L. M. and Georg, S. (2021), “Exploration of decision-contexts for CE in automotive industry”, Procedia CIRP, Vol.98, pp.19 - 24. DOI: https://doi.org/10.1016/j.procir.2020.11.005.

11. Sebastian, T., Siegfried, A., Clément, C., Josefine, D., Charlotte, T., Lukas, M. and Philipp, K. (2023), “Removing the finish line: How the CE will energize the automotive industry”, Capgemini invent, pp1 - 23.

12. Syed, W. H. R, Saurabh, A. and Qasim, M. (2023), “Automotive industry and industry 4.0-CEnexus through the consumers' and manufacturers’ perspectives: A case study”, Renewable and Sustainable Energy Reviews, Vol.183. DOI: https://doi.org/10.1016/j.rser.2023.113517.

13. Wurster, S. (2021), “Creating a CE in the Automotive Industry: The Contribution of Combining Crowdsourcing and Delphi Research”, Sustainability, Vol.13, No.12, pp.1-26. DOI: https://doi.org/10.3390/su13126762.